Project name

Ventilation and exhaust system of an energy storage container

Project background

The application scenario adopts the AC fan+power supply mode in the traditional mode, which is complex in structure and high in cost.

Solution

According to the characteristics of the industry and customer needs, customize the fan, support the AC to DC power supply mode, save the AC power supply, save costs, and simplify the product structure.

Product Overview

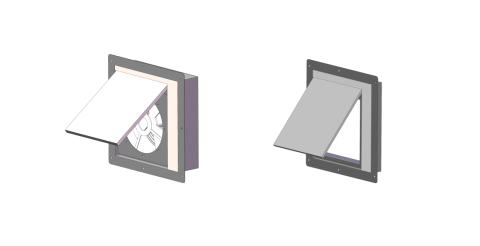

Ventilation and exhaust system is composed of ventilation electric louver and exhaust fan (electric louver+explosion-proof fan+control module) The ventilation and exhaust system of the energy storage container, together with the gas detector and alarm host, can prevent the explosion risk due to the concentration of combustible gas.

After receiving the alarm signal from the gas detector, the controller host sends a signal to the ventilation and exhaust system. When the concentration of fuel gas is higher than the threshold value, the electric louver of the exhaust fan is opened, the explosion-proof fan is opened, and the electric louver of ventilation is opened to discharge the combustible gas in the energy storage box. When the concentration of combustible gas drops below the threshold value, the controller host receives the signal to automatically close the ventilation and exhaust system.

When the ventilation and exhaust system encounters power failure during operation, the explosion-proof fan shall be closed and the electric shutter shall be open. When the power is off, press the shutter close button to close the shutter.

Product composition

2 air inlet electric louvers+1 explosion-proof exhaust fan (explosion-proof fan+electric louver)+1 controller=1 set

1. Technical parameters:

1.1 Fan air volume: 830CFM

1.2 Anti corrosion grade: C5

1.3 Protection grade: IP66

1.4 Working temperature range: - 40~60 ℃. It is required to meet the requirements of resisting the harsh conditions of snow, rain and salt fog and still having the function of air intake

1.5 Humidity range: 0~95%

1.6 Meet the thermal insulation requirements, the thermal insulation material shall meet the thermal conductivity ≤ 0.044W/mK, and the coverage shall be complete.

1.7 The fan harness interface adopts butt plug mode.

1.8 Fan noise ≤ 60dB

1.9 Total power of inlet and outlet fan < 400W

1.10 Explosion proof super grade: meet the explosion-proof requirements for hydrogen sites

2. Controller

2.1 Control logic:

Connect the gas detector signal to open and close the air inlet shutter and exhaust fan;

After the power is cut off, the explosion-proof fan is closed, the electric shutter is opened, and the electric shutter is closed manually if necessary;

Electrically manually open and close the air inlet electric shutter and explosion-proof exhaust fan;

2.2 The controller feeds back the working signals of fan and push rod, and the feedback signals are dry contact signals. Relay is preferred, MCU and software are not preferred.